Putting the brakes on air pollution: getting to grips with the TAMIC® solution to combat fine particle emissions

There are very few ways to capture the fine particle emissions generated by braking. TAMIC® is a pioneer on the market and can be fitted to trains as well as light and heavy goods vehicles. It’s a low-cost device that can protect the health of people exposed to air pollution.

There’s danger underfoot. Many people still don’t realise, but applying your car’s brake pedal can damage your health and that of others. The dust generated by braking – under the effect of friction and therefore heat – has a serious impact on health. It can increase the risk of lung cancer, as well as respiratory and neurodegenerative diseases. Even more worrying is that in 2020, an OECD report found that wear on brakes, tyres and road surfaces would soon be the main source of particulate emissions in the atmosphere linked to road traffic, ahead of exhaust fumes. Given the importance of these issues, in November 2022 the European Commission decided to regulate the fine particles generated by vehicle braking for the first time. The historic decision meant that a European automotive pollution standard – the “Euro 7/VII” – will come into effect from July 2025. But what can be done about capturing those particles? Over the last ten years, Tallano Technologies has been developing a solution that has proven to be extremely effective.

Suction systems for fine friction particles

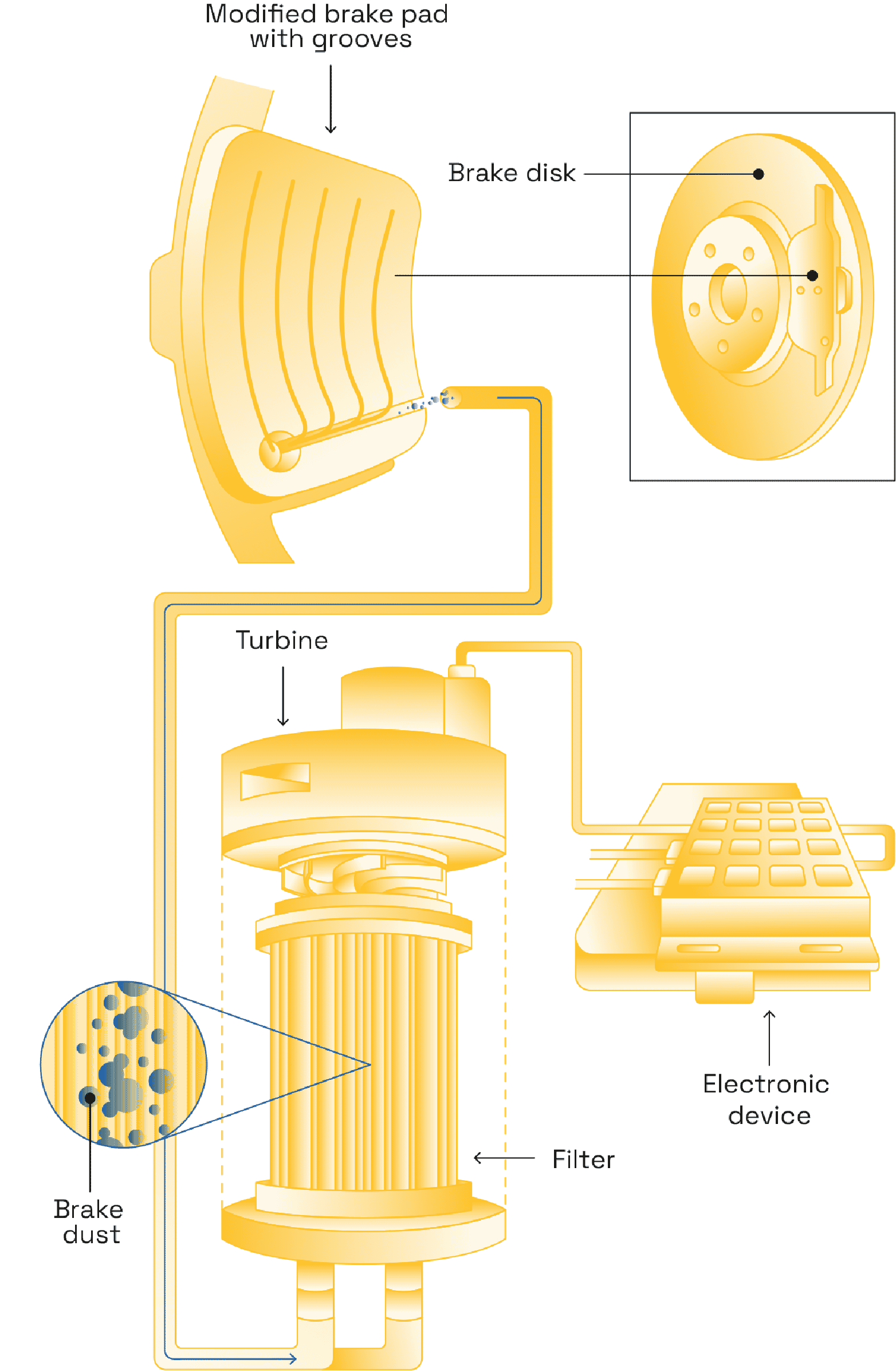

“The TAMIC® captures and retains a very large amount of fine particles during braking, ranging from a few microns to a few nanometres, but also larger particles, up to a few millimetres, which are not regulated, but which, without TAMIC®, find themselves on the road and then in runoff water and nature”, explains Loïc Adamczak, Chief Technology Officer at Tallano Technologies. Is this a green revolution? With a large portfolio of patents filed and published in many countries around the world, Tallano Technologies was the first Cleantech company to design, test with car and rail manufacturers, and then market a solution like this. It’s a major technological achievement that nips the problem in the bud. “The TAMIC® sucks the brake dust directly on contact, at the trailing edge, before the particles escape. We create one or more grooves – depending on how it is fitted. We use a pump to generate a vacuum in the groove and an air flow, which brings the particles to the installed filter”, says Loic Adamczak.

Air quality: proven and approved results

“Our system is optimised, it doesn’t operate when it’s not needed. On a vehicle, the TAMIC® creates the suction process when the brakes are applied, and continues for a few seconds afterwards. We call this the cleaning time, and it allows the particles to be moved to the filter. As part of this sequenced driving mode, and using the test protocol developed for the Euro VII standard, the TAMIC® eliminates around 70% of the fine particles emitted during braking”, says Loïc Adamczak. That efficiency can reach up to 90% in certain braking conditions, especially in urban areas. It’s the same story when the device is used in rail transport: tests carried out for two years on the RER C in Paris revealed that it retained 70% of fine particles during braking. As well as in tests, the TAMIC® has proven its worth under real conditions for trains and motor vehicles while ensuring that the brake system works safely.

A low-cost device for widespread deployment

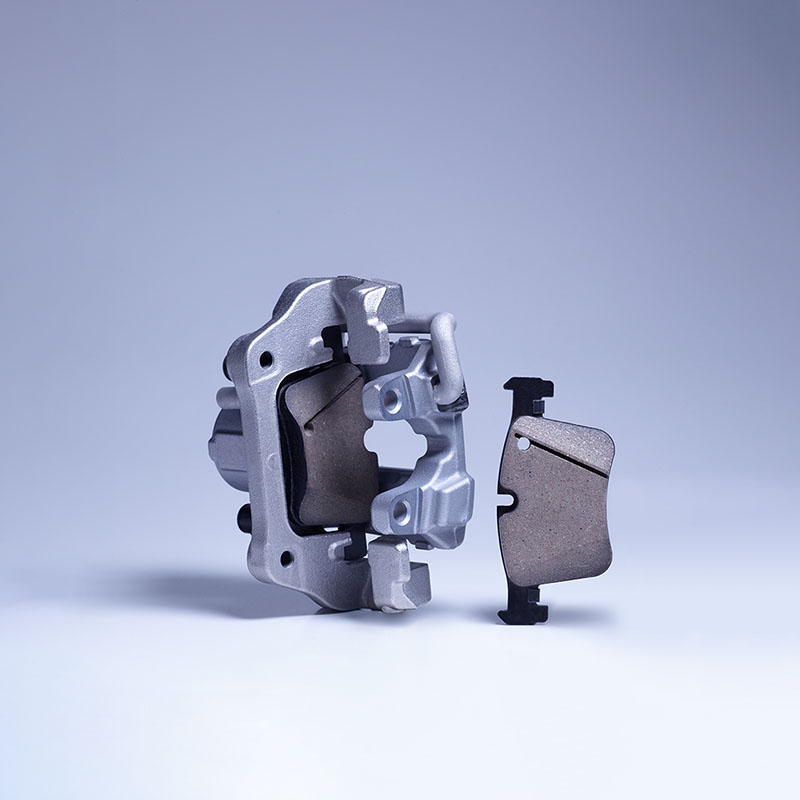

“TAMIC® is suitable for any type of vehicle, including light vehicles, heavy goods vehicles, trains and others”, says Loïc Adamczak. And that means electric vehicles too, which also emit fine friction particles. The device can be installed on new vehicles in association with car manufacturers or suppliers when a new model is released. It can also be fitted later, especially for heavy goods vehicles and trains, whose lifespans can reach 40 years. “Retrofits need to be tailor-made, because in addition to vast differences in braking systems, we also have to adapt to the layout and structure of each model so that our pumps and filtration boxes can be integrated properly. The TAMIC® must be adjusted on a case-by-case basis”, explains Loïc Adamczak. Tallano Technologies has set up a partnership with AKWEL to market this filtering system. It is efficient, easy to use and affordable. You’ve got it, the TAMIC® is the essential solution to make sure as many vehicles as possible are Euro 7/VII-compliant.